Have you ever asked yourself how industries or even simple plumbing systems manage the flow of liquids and gases so smoothly? The answer lies in valves, and two of the most common types are ball valves and butterfly valves.

Both are widely used, both are reliable, and both bring unique benefits to different applications. To understand how they work and where they are used, let’s talk in simple terms about their differences and why they are so useful in many projects.

Understanding Ball Valves and Butterfly Valves

Valves are like traffic controllers for fluids. They decide when to stop the flow, when to allow it, and how much of it should pass.

Here, ball valves and butterfly valves are two very popular types, each with its structure and style of operation. Both are built for strength, reliability, and ease of use, which is why they are seen in industries, homes, and large infrastructure projects.

Both of them are used in pipelines, water treatment, chemical plants, power stations, and even in smaller setups like household plumbing. Even though they share the same purpose, their construction and working methods make them fit for different situations.

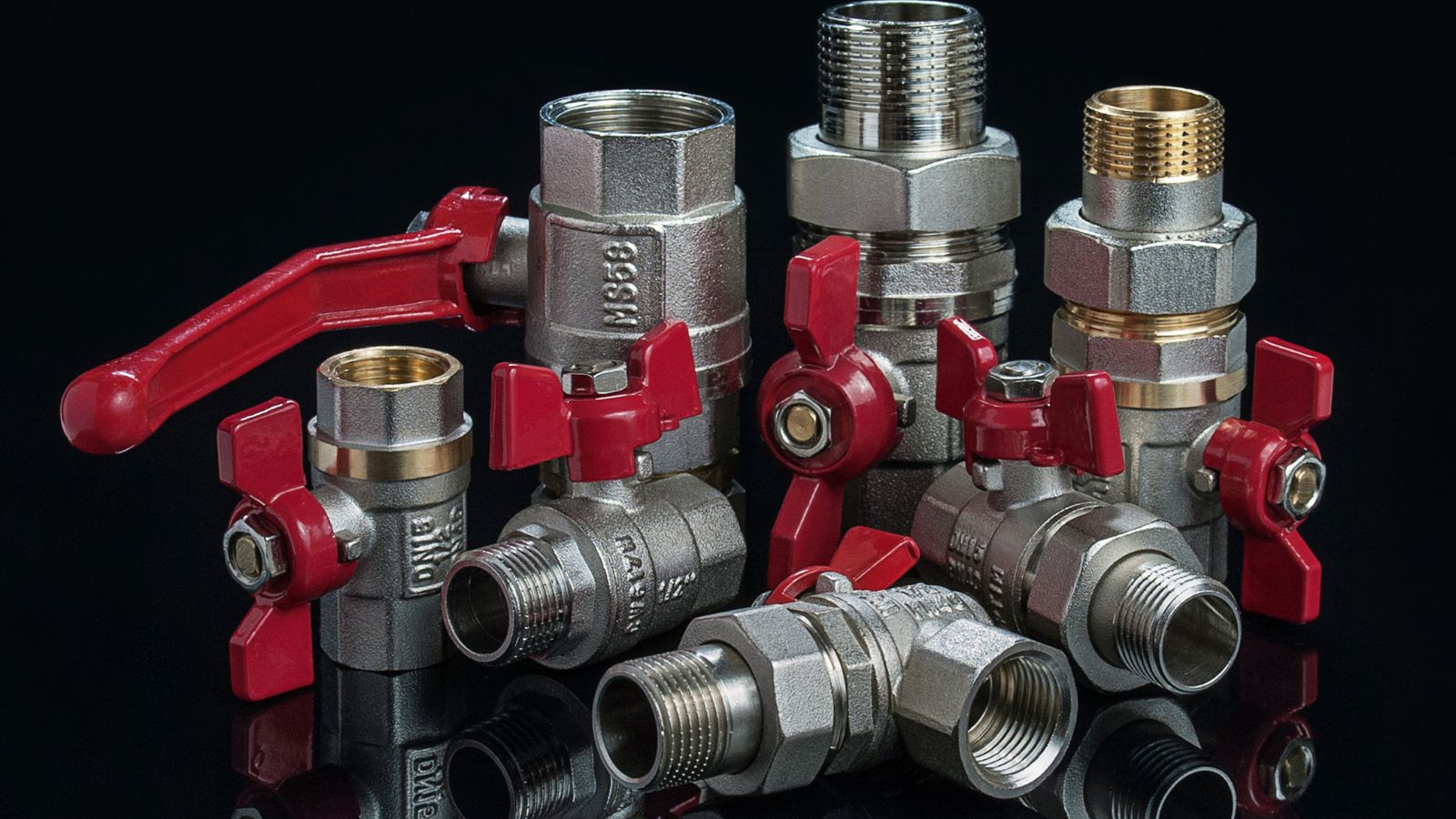

What is a Ball Valve?

A ball valve uses a round ball with a hole in the middle to control flow. When the hole lines up with the pipeline, fluids pass easily. When the ball is turned, the hole closes, and flow stops. This simple design makes it very reliable. And, ball valves are known for providing a tight shut-off. They are quick to operate, usually with a quarter turn, and they can handle high pressure and temperature. They are widely used in industries that need secure flow control with no leakage.

What is a Butterfly Valve?

A butterfly valve works differently. Instead of a ball, it has a flat disc that rotates inside the pipe. When the disc is parallel to the flow, the fluid moves freely. When the disc is turned, it blocks the passage and controls how much fluid can pass.

Butterfly valves are known for their lightweight structure and easy operation. They are excellent for large pipelines because they take up less space and are easier to install. Their design also allows quick operation, making them efficient for industries where flow needs to be managed smoothly.

Key Differences Between Ball Valves and Butterfly Valves

Both ball valves and butterfly valves do the job of controlling flow, but they go about it in different ways. This difference in design and function makes each one better suited for specific types of work. Understanding these differences helps in choosing the right one for the right purpose.

Each has its own style of working and each is perfect in its own way. The main differences lie in their structure, flow control, size, and where they are used.

Structural Differences

The ball valve has a spherical ball at its core, while the butterfly valve has a flat disc. This difference in structure also affects their size and weight. Ball valves are often heavier and bulkier, while butterfly valves are more compact and lighter. This makes butterfly valves easier to install in larger systems with space considerations.

Flow Control

Ball valves provide excellent shut-off with no leakage. They are ideal when the flow needs to be completely stopped or fully open. On the other hand, butterfly valves allow more control over how much fluid passes through. They can be adjusted smoothly for partial flow, which is useful in many industrial processes.

Operation

Both ball valves and butterfly valves are quick to operate with a quarter turn of the handle. Ball valves are best for on/off applications where flow is either open or closed. Butterfly valves are better when you need fine control over flow, as the disc can be set at different angles to regulate passage.

Size and Space

Ball valves, because of their ball mechanism, take up more space and are usually used in smaller to medium pipelines. Butterfly valves are slim and lightweight, making them suitable for very large pipelines where weight and space matter.

Uses of Ball Valves and Butterfly Valves

Both valves are widely used, but their applications vary depending on their strengths. Ball valves are valued for their tight shut-off, while butterfly valves are valued for their compact size and ease in large systems.

They are seen across industries like water treatment, oil and gas, power generation, chemical processing, and even in residential plumbing systems. Their uses are broad, but each valve type shines in its area.

Uses of Ball Valves

Ball valves are commonly used where a strong and secure shut-off is needed. They are seen in:

- Oil and gas pipelines

- Chemical plants

- Power stations

- Household plumbing systems

They are perfect for applications that require reliable sealing and handling of high pressure.

Uses of Butterfly Valves

Butterfly valves are commonly used in large pipelines and where flow needs to be controlled easily. They are seen in:

- Water distribution systems

- Wastewater treatment plants

- Food and beverage industries

- Fire protection systems

They are perfect for applications that require lightweight, space-saving, and easy operation.

Why Both Valves Are Important

Both ball valves and butterfly valves bring unique advantages. Ball valves offer secure shut-off and reliability, while butterfly valves offer compact size and easy control in large systems. The decision to use one over the other depends on the size of the system, the pressure involved, and the type of control needed.

Together, they show how engineering solutions can be adapted to different needs. By choosing the right valve, industries save time, reduce costs, and keep operations running smoothly.

Ball Valves for Strong Sealing

Ball valves are chosen when the requirement is zero leakage and full control of high-pressure fluids. Their structure makes them reliable for industries that cannot afford even small leaks. This strong sealing ability makes them trusted across sensitive applications.

Butterfly Valves for Large Pipelines

Butterfly valves are chosen when the requirement is easy handling and smooth flow regulation in very large systems. Their lightweight design makes them simple to install and maintain, even in places where other valves might feel too bulky.

To Sum Up

Ball valves and butterfly valves are two of the most important tools in fluid control. Each has its strengths, and each plays a key role in industries and daily life. Ball valves bring strong sealing and high-pressure handling, while butterfly valves bring light weight, easy operation, and smooth flow regulation.

Instead of comparing which one is better, it is wiser to understand how each serves different needs. Both are valuable in their way, and both continue to be trusted in small systems and large industrial projects alike. Their presence ensures smooth operations, safety, and reliability across countless applications.